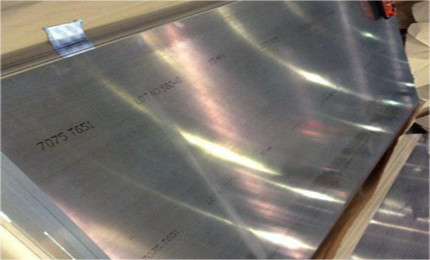

Product brief introduction

1, 7075 aluminum alloy is a kind of cold treatment forging alloy, high intensity, far more than mild steel.

7075 is one of the most powerful alloy commercial.

Subjected to heat treatment, can reach very high strength characteristics.

7075 material is generally add a small amount of copper and chromium alloy, such as department of 7075 - T651 aluminum alloy is top grade, is praised as the most excellent products in aluminum alloy, high strength, much better than any of the mild steel.

The alloy with good mechanical and anodic reaction.

2, 7075 mainly contain zinc.

Also belong to the aviation series, is copper alloy, aluminum and magnesium zinc is heat treatable alloys, belongs to hard aluminum alloy, have good wear resistance. 7075 aluminum plate is by eliminating stress, not deformation, warping after processing. All the 7075 super ultra thick aluminum plate by ultrasonic detection, can guarantee without sand holes, impurities. 7075 aluminum sheet of high thermal conductivity, can shorten the molding time, improve work efficiency.

Main features are high hardness 7075 is high hardness, high strength aluminum alloy, often used in the manufacture of aircraft structures and futures.

It requires high strength, strong corrosion resistance of high stress structure, mould manufacturing.

Product Parameter

| Brand | Old Brand | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Element | Rest | Al | |

| Single | Totle | |||||||||||||

| 7075 | — | 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1-2.9 | 0.18-0.25 | 5.2-6.2 | 0.06 | — | — | 0.05 | 0.15 | Remain |

Technical Equipment

7075 is mainly used in the manufacture of aircraft structure and the other requests high strength, corrosion resistance of high stress structure, such as plane, the wing wall plate, purlin, etc.

Good plastic after solid solution treatment, heat treatment reinforcement effect is good, below 150 degrees have good strength, and has very good strength at low temperature, welding performance is poor, has a tendency to stress corrosion cracking.

Also widely used in the mold processing, machinery and equipment, fixture, aerospace industry, blow molding (bottle) model, ultrasonic plastic welding mold, golf head, shoe's molding, paper plastic mould, foaming molding mould, wax mold, mechanical equipment, used to make high-end aluminum alloy bicycle frame.

In 2014 for the first time as a smartphone OPPO N3 fuselage material being used.