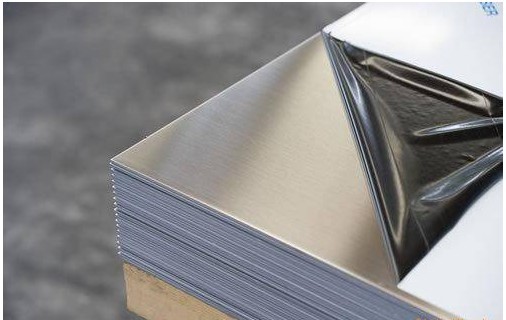

Product brief introduction

Duplex stainless steel 2205 standard: ASTM A240 / A240M - 01 duplex stainless steel 2205 alloy is by 22% chromium, 2.5% nitrogen and 4.5% molybdenum nickel alloy consisting of duplex stainless steel.

It has high strength, good impact toughness and good overall and partial stress corrosion resistance.

Product Parameter

C≤0.030 Mn≤2.00 Si≤1.00 p≤0.030 S≤0.020 Cr 22.0~23.0 Ni 4.5~6.5 Mo3.0~3.5 N0.14~0.20

Performance added: the main ingredients: 22 cr - Ni - 3.2 5.3 Mo - 0.16 N;

National standard: 329 NAS j3l, UNS S32205 / S31803, DIN/EN, ASTM A240, ASME SA - 240-1.4462;

Mechanical properties, tensile strength: 640 mpa sigma b p;

25% elongation, the delta p;

Typical conditions: dilute sulphuric acid 20%, below 60 ℃, the annual corrosion rate < 0.1 mm;

Form a complete set of welding wire: ER2209.

Technical Equipment

1. 2205 duplex stainless steel alloy with 316 l and 317 l austenitic stainless steel, alloy 2205 in pitting corrosion and crevice corrosion resistance is superior, it has the very high corrosion resistance, compared with austenitic, its lower thermal expansion coefficient, thermal conductivity is higher.

2. 2205 duplex stainless steel alloy compared with austenitic stainless steel, its compressive strength is its two times, compared with 316 l and 317 l, designers can reduce the weight.

Especially suitable for 2205 alloy + 50 ° F / 600 ° F temperature range, in the case of restricted (especially for welding structure), can also be used to lower the temperature.